Efficient Production

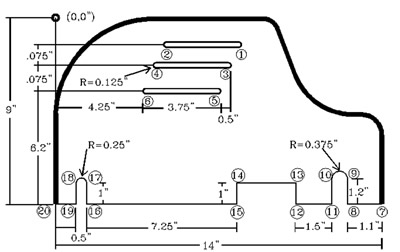

At the PMW plant in Raleigh, plastic products are designed and manufactured. One product is a key cutter safety cover that must be routed using an automated routing machine.

The Camtasia Studio video content presented here requires JavaScript to be enabled and the latest version of the Adobe Flash Player. If you are you using a browser with JavaScript disabled please enable it now. Otherwise, please update your version of the free Adobe Flash Player by downloading here.

In designing an efficient process to manufacture these covers, one problem was to determine the most efficient router path to make the required cuts. Efficiency could be determined by minimizing the total distance that the router will need to travel to make all the cuts and return to the starting position.

Even though the time saved on one item may be small, when thousands of an item are to be made, saving time and wear on the machinery translates into company savings and higher profits.